In process manufacturing, such as food and beverage or chemicals, the bill of materials is known as a production recipe. The software should have the ability to generate financial reports and provide insightful analysis of production performance. Let’s explore the essential features that every excellent accounting software for manufacturing should include. It involves calculating the weighted average cost of all units available for sale during a given period. The first-in-first-out (FIFO) inventory valuation method assumes that the first unit you manufacture is the first one you sell.

Process costing

You might look at each project in detail – down to costs, materials, and overhead. You need to think beyond profit and loss to manufacturing costs such as the costs of materials, plus the manufacturing accounting cost to convert these materials into products. This is necessary, for example, to understand how you should be pricing your product and how to achieve or exceed your set profit margins.

Table of contents

Constraint analysis involves finding the bottleneck in the manufacturing process (if any) and advising the production department regarding the impact on throughput of changes to the flow of work through that bottleneck. The https://www.bookstime.com/ analysis can include an examination of the inventory buffer in front of the constraint and the existence of any upstream sprint capacity. This can be among the most important functions of manufacturing cost accounting.

Real Estate

Direct Labor Costs represent the wages, benefits, and insurance paid to the people who run equipment, assemble parts, and other roles that impact the production of goods. A good rule of thumb for determining if a cost is direct or indirect is to ask whether the cost increases as production increases. Integrating or upgrading your accounting software, though important, runs the risk of increasing errors in your recorded business data. Here are some best-practice tips for conducting successful manufacturing accounting. It’s wise for a manufacturing accountant to follow shifting customer trends as a change in demand could drastically alter the cost landscape for the business.

- An automated inventory management system facilitates accurate inventory accounting and can greatly reduce the time and cost required to manage physical stock.

- It standardizes operations across locations, including accounting and reporting requirements.

- At the end of the year, it is left with unfinished inventory (or inventory that was left over from its planning stage) worth $150,000.

- Manufacturing accounting systems offer valuable visibility into key aspects of inventory management, encompassing goods acquisition, stock valuation, and the calculation of moving average costs (MAC).

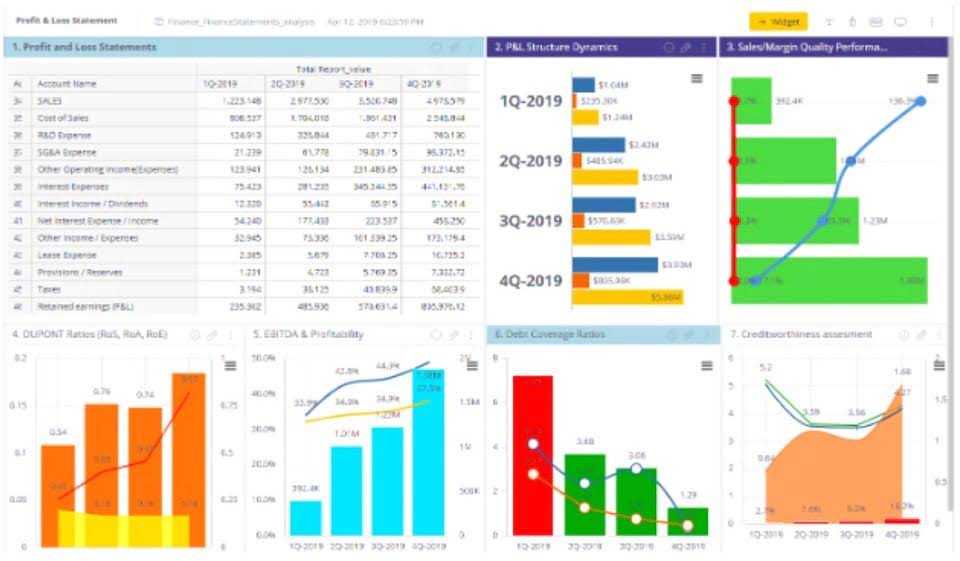

- Manufacturers demand powerful, intuitive financial reporting with customizable dashboards to monitor costs, profitability, cash flow, and financial health in real-time.

- Oracle NetSuite OneWorld is a cloud-based ERP for managing end-to-end local and global manufacturing processes and operations.

- Most manufacturing ERP providers require potential clients to request a custom quote and, so, do not offer pricing information online.

Determine which costing methods for manufacturing produces the most accurate calculations and the most opportunity for growth. Also consider unique situations, such as when employees purchase items for production using a company credit card. These costs must be correctly allocated to the right job or product or order, and manufacturing accounting software might be a big help. Regardless if the manufacturer works in discrete manufacturing, distribution, or supply chain, manufacturing cost accounting is a unique challenge.

Calculating Cost of Goods Manufactured (COGM) and Cost of Goods Sold (COGS)

This can take the form of team-specific milestone parties or point-based prizes for trainees who have mastered key concepts. Once you’ve trained leadership team members from each function, they should then be responsible for training their own teams. By allowing team leads to train their own teams, function-specific trainees receive more pointed instructions on how the system can benefit them based on their roles. Many or all of the products featured here are from our partners who compensate us.

- This software can be used to extract data and analyze trends, improve efficiency, and make the best business decisions.

- This allows you to analyze data and derive insights into the overall financial position of your business processes.

- We follow strict ethical journalism practices, which includes presenting unbiased information and citing reliable, attributed resources.

- Sign up for a demo today and unlock the power of streamlined manufacturing operations.

- Manufacturing businesses need to maintain a close watch on their books to ensure they generate the required amount of profit relative to their costs since they create products from scratch.

How confident are you in your long term financial plan?